Mastering industrial electrical schematics is crucial for troubleshooting and innovation․ Learn to identify components like optocouplers and MOSFETs, understand their interactions, and interpret complex circuit logic effectively․

Understanding the Importance of Electrical Schematics in Industrial Settings

Electrical schematics are essential for industrial operations, enabling efficient troubleshooting, maintenance, and innovation․ They provide a visual representation of complex systems, allowing technicians to identify components, trace circuits, and understand interactions․ This clarity ensures safety, reduces downtime, and optimizes performance․ Proficiency in reading schematics is a fundamental skill for engineers and maintenance professionals, bridging the gap between theoretical knowledge and practical application in industrial automation and control systems․

Overview of the Key Components and Symbols

Industrial electrical schematics consist of standardized symbols representing components like resistors, capacitors, and transistors․ These symbols are essential for identifying circuit elements and their functions․ Key components include wires, terminals, and reference designators, which label parts for clarity․ Understanding these symbols and their interactions is fundamental for interpreting schematic diagrams accurately and efficiently, ensuring effective troubleshooting and system maintenance in industrial settings․

Understanding Basic Electrical Symbols and Notations

Mastering basic electrical symbols and notations is essential for reading schematics․ Recognize components like resistors, capacitors, and transistors to understand their roles in circuit analysis․ This knowledge aids in interpreting and designing schematic diagrams effectively․

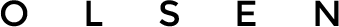

Common Component Symbols in Industrial Schematics

Industrial schematics use standard symbols for components like resistors, capacitors, inductors, and diodes․ Transformers are represented by two coils, while MOSFETs and optocouplers are shown with specific icons․ Recognizing these symbols is crucial for understanding circuit functionality․ Each symbol conveys the component’s role, such as resistors reducing voltage or capacitors storing energy․ Familiarity with these symbols aids in troubleshooting and designing circuits․ Always consult a reference guide for unfamiliar symbols to ensure accurate interpretation and application․

Passive vs․ Active Components: Identification and Function

In industrial schematics, passive components, like resistors, capacitors, and inductors, operate without external power, storing or dissipating energy․ Active components, such as transistors, diodes, and ICs, require a power source to function, amplifying or controlling signals․ Identifying these components is vital for understanding circuit operation․ Passive components are typically two-terminal devices, while active components often have multiple terminals, enabling complex functionalities․ Accurately distinguishing between them ensures proper circuit analysis and troubleshooting, essential for maintaining industrial electrical systems․ Always refer to the schematic legend for clarification if unsure․

The Structure of Industrial Electrical Schematics

Industrial electrical schematics follow an organized approach, utilizing a clear visual hierarchy and standard arrangement of components and connections․ This structure ensures readability and simplifies complex systems for technicians and engineers․

Standard Arrangement of Components and Wires

In industrial schematics, components are typically arranged to reflect their logical sequence in the circuit․ For example, optocouplers and MOSFETs are positioned to clearly show their role in signal transmission and power control․ Wires are drawn to minimize clutter, with straight lines representing connections between devices․ This standardized layout helps technicians quickly identify inputs, outputs, and control paths, ensuring efficient troubleshooting and system maintenance․

Understanding the Hierarchy and Layout of Schematics

Industrial electrical schematics are organized hierarchically, with components arranged to reflect their functional sequence․ The layout typically flows from left to right, showing the progression of signals or power distribution․ This structured approach helps technicians identify inputs, processing stages, and outputs․ By following the logical flow, one can trace circuit paths and understand how components interact․ This systematic arrangement simplifies troubleshooting and ensures clarity in complex industrial systems․

Reference Designators and Labels

Reference designators label components, ensuring clarity and traceability․ Labels like R1 or L1 uniquely identify parts, aiding in circuit navigation and troubleshooting․ Consistent labeling enhances schematic readability and efficiency․

Deciphering Reference Designators for Components

Reference designators are standardized labels assigned to components, such as R1 for resistors or Q1 for transistors․ These unique identifiers help in quickly locating parts on schematics․ Understanding these labels is crucial for interpreting circuit functionality and troubleshooting․ Each designator typically starts with a letter indicating the component type, followed by a number for uniqueness․ This system ensures consistency and clarity, enabling efficient navigation and analysis of complex industrial electrical diagrams․ Proper decoding of these labels is essential for accurate schematic interpretation and maintenance tasks․

Labeling Conventions for Wires and Connections

Wires and connections in industrial schematics are labeled with standardized codes to ensure clarity and safety․ Colors often denote specific functions, such as red for phase lines or green for grounding․ Labels may include voltage levels or purposes, like 24V or control signal․ These conventions help technicians quickly identify wire roles and ensure proper connections, reducing errors and enhancing efficiency in circuit analysis and troubleshooting․

Reading the Schematic Step-by-Step

Begin by identifying the circuit’s starting point, such as a power source․ Trace wires and components sequentially, noting connections and interactions to understand the overall functionality․

Identifying the Starting Point of the Circuit

Locating the circuit’s starting point is essential for understanding its flow․ Typically, this is a power source, such as a battery or transformer, or a terminal marked as the input․ Look for clear labels or ground symbols, which often indicate the beginning․ Tracing from this point ensures a logical progression through the circuit’s components and connections, making it easier to follow the electrical path and diagnose issues effectively․

Tracing the Circuit Path and Connections

Tracing the circuit path involves following the flow of electricity step-by-step․ Start from the identified starting point and use visual cues like lines, arrows, and symbols to track connections․ Pay attention to junctions, splits, and loops, as these indicate multiple paths or parallel components․ Understanding how components like resistors, capacitors, and ICs interact within the circuit enhances your ability to interpret the schematic accurately and identify potential troubleshooting points․

Recognizing and Interpreting Component Interactions

Understanding how components interact is key to interpreting schematics․ Components like sensors, actuators, and logic gates work together to form functional blocks․ Analyze how inputs from sensors trigger outputs through control circuits․ Recognize how passive components (e․g․, resistors, capacitors) condition signals, while active components (e․g․, transistors, ICs) amplify or process them․ This interaction reveals the circuit’s logic and functionality, aiding in troubleshooting and design optimization․

Interpreting Circuit Logic and Functionality

Understanding inputs, processing, and outputs reveals the circuit’s purpose․ Identify control circuits for decision-making and power circuits for energy distribution to interpret functionality accurately․

Understanding Inputs, Processing, and Outputs

In industrial circuits, inputs are signals or sensors triggering actions, while processing involves logic or decisions made by components like PLCs or controllers․ Outputs are the resulting actions, such as activating motors or alarms․ Together, they form a clear workflow: inputs provide data, processing interprets it, and outputs execute the response․ This structure simplifies troubleshooting and ensures efficient system operation by breaking down complex functions into manageable, logical steps․

Identifying Control and Power Circuits

In industrial schematics, control circuits manage logical operations, such as signals from sensors or PLCs, while power circuits handle high-current loads like motors or actuators․ Control circuits often use relays or contactors, while power circuits rely on heavy-duty components; Identifying these separately is crucial for maintenance, as control circuits dictate system logic, and power circuits execute physical actions․ This separation ensures safe and efficient troubleshooting and operation of industrial electrical systems․

Recognizing Circuit Protection and Safety Devices

Circuit protection and safety devices, such as fuses, circuit breakers, and surge protectors, are essential for preventing damage and ensuring safe operations․ These components are typically located at entry points or near critical equipment․ Fuses interrupt overcurrent, while circuit breakers provide resettable protection․ Surge protectors guard against voltage spikes․ Identifying these devices in schematics helps technicians isolate faults, prevent equipment damage, and maintain a safe working environment․ Their proper placement and rating are vital for reliable system performance and operator safety․

Practical Examples and Applications

Industrial electrical schematics are applied in PLC modules, motor control circuits, and automation systems․ A case study on a simple control circuit demonstrates how components like optocouplers and MOSFETs function in real-world scenarios․

Case Study: Analyzing a Simple Industrial Control Circuit

A case study on a PLC I/O module illustrates how to interpret interactions between components․ The circuit starts with an optocoupler isolating inputs, followed by a crowbar circuit for protection, and ends with an output MOSFET controlling the load․ This example demonstrates how to trace signal flow, identify component functions, and understand the logic behind industrial control systems, providing practical insights into real-world applications of schematic reading skills․

Applying Schematic Reading Skills to Real-World Scenarios

Applying schematic reading skills to real-world scenarios involves troubleshooting, designing, and maintaining industrial systems․ For instance, understanding PLC I/O modules and their interactions with optocouplers and MOSFETs is critical for industrial automation․ By mastering these skills, professionals can efficiently diagnose faults, optimize circuits, and ensure system reliability․ Tools like simulation software and online courses further enhance practical application, enabling technicians to tackle complex challenges in manufacturing and process control effectively․

Troubleshooting Using Electrical Schematics

Electrical schematics are vital for diagnosing faults and repairing industrial systems․ By tracing circuits and identifying anomalies, technicians can efficiently locate and resolve issues, ensuring optimal performance․

Identifying Faults and Anomalies in the Circuit

Identifying faults in industrial circuits requires understanding component interactions and tracing paths․ By recognizing unusual conditions, such as optocoupler failures or MOSFET malfunctions, technicians can pinpoint issues․ Automated tools and reference designators help locate anomalies efficiently․ This systematic approach ensures accurate diagnostics and minimizes downtime, crucial for maintaining industrial operations and safety standards․

Using Schematics for Diagnostic and Repair Purposes

Schematics are essential for diagnosing and repairing industrial circuits․ By analyzing the circuit layout, technicians can identify faulty components, such as optocouplers or MOSFETs, and trace their connections․ Reference designators guide the repair process, enabling precise replacements․ This method ensures efficient troubleshooting, reduces downtime, and guarantees system reliability․ Regular practice enhances the ability to interpret schematics accurately, making it a vital skill for maintaining industrial electrical systems effectively․

Additional Resources for Learning

Explore books like A Beginner’s Guide to Reading Schematics and online courses for in-depth learning․ Utilize tools like OrCAD for hands-on practice and schematic analysis․

Recommended Books and Online Courses

Enhance your skills with resources like A Beginner’s Guide to Reading Schematics, available as a free PDF․ Online platforms offer courses on industrial schematic interpretation, while tools like OrCAD provide practical design experience․ Websites such as https://go․beeautomation․co․uk/free-training-yt offer comprehensive training materials․ These resources cater to both beginners and professionals, ensuring a solid foundation in reading and interpreting industrial electrical schematics effectively․

Tools and Software for Schematic Drawing and Analysis

Utilize tools like OrCAD for schematic drafting and simulation․ PCB design software offers advanced features for creating and analyzing circuits․ Tools like SPICE enable simulation and testing of designs․ Modern solutions also include AI-driven platforms that assist in interpreting and optimizing schematics․ These resources streamline the workflow, enhance accuracy, and support both educational and professional applications in industrial electrical schematic analysis․

Mastering industrial electrical schematics is a fundamental skill for troubleshooting and innovation․ Continuous practice and learning ensure proficiency in reading and interpreting complex diagrams effectively․

Summarizing Key Takeaways for Effective Schematic Reading

Understanding industrial electrical schematics requires mastering component symbols, tracing circuit paths, and interpreting interactions․ Recognizing reference designators and labels is essential for clarity․ Practice identifying passive and active components, such as optocouplers and MOSFETs, and their roles in circuit logic․ Continuous practice with real-world diagrams enhances troubleshooting skills and ensures effective interpretation of complex industrial electrical systems․

Encouraging Continuous Practice and Skill Development

Regular practice with industrial electrical schematics is essential for mastery․ Engage with online courses, books, and practical exercises to reinforce learning․ Use tools like simulation software to visualize circuit behavior․ Apply skills to real-world scenarios, such as troubleshooting or designing circuits, to build confidence and proficiency․ Consistent practice ensures long-term retention and enhances problem-solving abilities in industrial electrical systems․